LP Appliances- flame safety

My main troubleshooting philosophy has always been that in order to figure out what is wrong with an appliance or system, you need to understand how it works.

LP Appliances in RVs all- with the exception of the stove top burners- have some sort of flame detection and safety circuit, which senses whether a flame is burning, and shuts off the flow of gas if it isn’t. Through the years, there have been 4 major types of systems- all of which are still in use.

The major types are:

- Mechanical

- Thermo-electric

- Thermo-electric hybrid

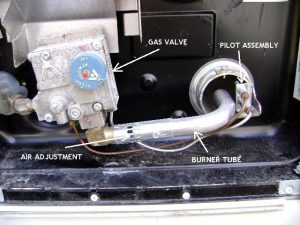

Pilot type Atwood Water Heater

- Pure electronic (a.k.a. DSI)

Today I will concentrate on the thermo-electric type, which , which uses a pilot flame and a thermocouple.

In new RVs, the major appliance which uses a pilot/thermocouple safety system is the water heater- though some new LP ovens use them as do some of the smaller refrigerators. In the past LP furnaces used this type of system as well, but most of those have reached the end of their useful life.This type of safety system can be recognized by the fact that you always have to push, pull, or turn something and hold for a bit after you light the pilot (or flame)

The thermo-electric pilot type system has 3 major parts- the pilot burner (picture), the Thermocouple (picture), and the Gas valve/Thermostat.

The thermocouple is a device which- in this application- produces a very small electric current when heated by the pilot flame. This current is used to hold open a safety valve, allowing the LP gas to flow to the pilot and main burner.

In this picture (click to enlarge), I am heating the end of a thermocouple with a small flame, I have the meter set on millivolts and have it hooked to the output end of the thermocouple. The flame is quite small (its there though- trust me), but the thermocouple is still putting out over 10 millivots. Normal output is between 15 and 30 millivolts. A side note- older furnaces would use what is called a thermopile, which is basically a bunch of thermocouples put together to produce enough current to actually operate a valve- and not simply hold one open as the thermocouple does in this use.

A point I want to bring up here is that the end of the thermocouple that screws in to the gas valve is actually an electrical connection- Notice the insulator between the very tip end and the outer ground shield. Over tightening this connection can crush the insulator and short out the voltage produced by the thermocouple, keeping it from holding the safety valve open. Standard procedure is to tighten finger tight plus 1/4 turn, adding 1/8 turn if needed.

Being an electrical connection, oxidation on the tip can also influence performance (this happens a lot on older Dometic refrigerators- more on that later).

The last part of this system is the safety valve, which on a water heater is inside the gas valve/thermostat.  This valve has a small magnet and coil inside which uses the small current produced by the thermocouple to hold a valve (the plunger in this picture) open- once you have opened it by pushing, pulling or turning something.

This valve has a small magnet and coil inside which uses the small current produced by the thermocouple to hold a valve (the plunger in this picture) open- once you have opened it by pushing, pulling or turning something.

So- the basic requirements for this system to work are:

- A large enough pilot flame to heat the end of the thermocouple

- A thermocouple which is producing a large enough current to hold the safety valve open.

- A complete circuit between the thermocouple and the safety valve (more on this later)

- A safety valve which is operational.

Once you know how the system is designed to work, and what each part does, troubleshooting a fault becomes much easier.

Comments

Tell me what you're thinking...

and oh, if you want a pic to show with your comment, go get a gravatar!